Titanium Carbide Density Essentials

(density of tic)

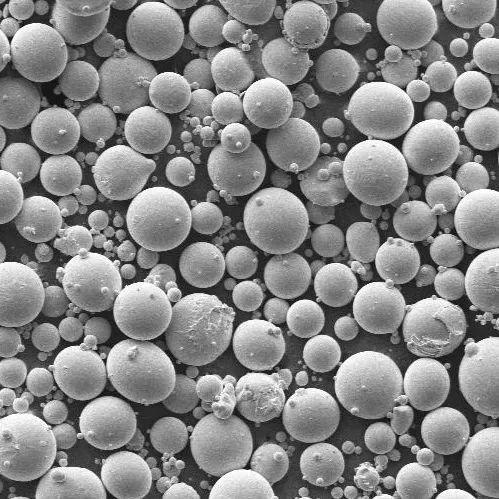

Titanium Carbide, commonly abbreviated TIC, possesses a high density crucial for its performance. Its density typically measures approximately 4.92 grams per cubic centimeter (g/cm³). This significant density arises from the atomic weights of its constituent elements, titanium and carbon, packed tightly within its crystal lattice structure.

This high density is intrinsically linked to TIC’s renowned properties. It directly contributes to the material’s exceptional hardness, ranking among the hardest known materials. High density also enhances TIC’s wear resistance, making it incredibly durable against abrasion and erosion. Furthermore, the density supports good thermal conductivity, aiding in heat dissipation from localized areas like cutting edges.

Understanding TIC’s density is vital for engineers and material scientists. It influences the weight of components, a critical factor in aerospace or automotive applications where mass reduction is key. The density also impacts the material’s behavior under mechanical stress and thermal cycling. Compared to other ceramics, TIC’s density is higher than alumina (Al₂O₃ ~3.97 g/cm³) but lower than tungsten carbide (WC ~15.6 g/cm³). It significantly outperforms most steels in terms of hardness and wear resistance relative to its weight.

(density of tic)

TIC’s combination of high density, extreme hardness, and chemical stability makes it indispensable. It’s extensively used in cutting tools, abrasion-resistant parts, coatings, and wear plates. Its density underpins the performance that allows TIC to excel in demanding industrial environments where longevity and durability are paramount. Remember this key figure: 4.92 g/cm³ – a fundamental property enabling TIC’s remarkable capabilities.

Inquiry us

if you want to want to know more, please feel free to contact us.