Titanium TI versus Titanium Carbide TIC are both crucial materials in tooling but serve different purposes. Understanding their strengths helps select the right material for the job. Pure Titanium TI is a strong lightweight metal known for excellent corrosion resistance and biocompatibility. It finds extensive use in aerospace components medical implants like joint replacements and chemical processing equipment where its inertness is vital. However TI is relatively soft compared to many tool steels and can wear quickly under abrasive conditions.

(ti vs tic)

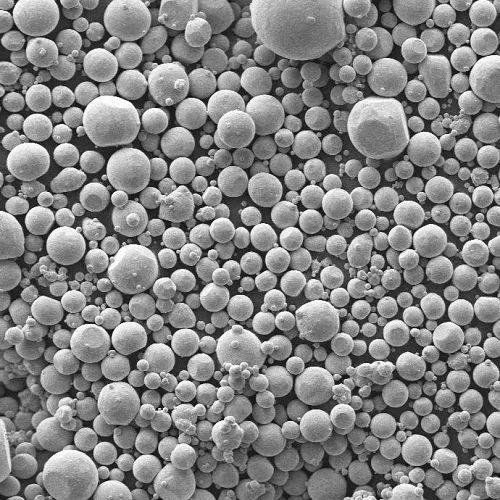

Titanium Carbide TIC is a ceramic compound formed by combining titanium with carbon. This process creates an extremely hard wear resistant material. TIC is rarely used alone as a bulk tool due to its inherent brittleness. Instead its primary application is as a reinforcing phase in composite materials called cemented carbides. Here TIC particles are sintered with a metallic binder usually cobalt or nickel creating cutting tools inserts and wear parts. These tools excel in high speed machining applications machining abrasive materials and situations demanding exceptional wear resistance and high temperature stability.

(ti vs tic)

The key difference lies in their fundamental properties. TI offers good strength and toughness with superior corrosion resistance making it ideal for structural and biomedical uses. TIC delivers extreme hardness and wear resistance but lacks toughness making it perfect as a reinforcing agent in cutting tools for demanding industrial machining. Essentially TI is the tough versatile metal while TIC provides the hard cutting edge in composite tool materials. Choosing between them depends entirely on whether you need a structural biocompatible metal TI or an ultra hard reinforcing compound TIC for cutting edges.

Inquiry us

if you want to want to know more, please feel free to contact us.