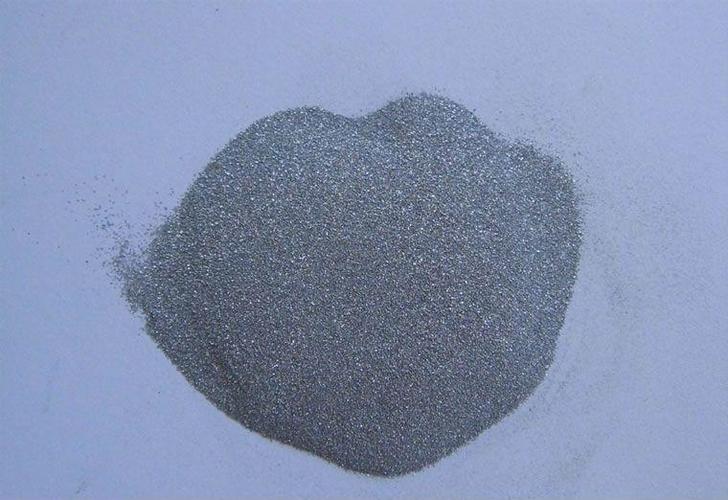

Titanium Carbide Blades Cutting Edge Performance Titanium carbide blades represent a significant leap in cutting tool technology. These blades are not pure titanium but rather feature a coating or composite involving titanium carbide TiC. This compound is renowned for its extreme hardness ranking close to diamonds on the Mohs scale significantly harder than steel. This inherent hardness translates directly to exceptional wear resistance. Blades retain their sharp cutting edge far longer than traditional steel counterparts reducing the need for frequent sharpening. They exhibit impressive toughness resisting chipping and cracking under demanding cutting tasks. The manufacturing process often involves sintering titanium carbide particles together at high temperatures or applying a thin hard coating to a tough steel substrate. This combination leverages the hardness of TiC with the resilience of steel. Applications span many fields. High end kitchen knives utilize titanium carbide coatings for long lasting sharpness. Industrial cutting tools saw blades and drill bits benefit from extended life in machining hard materials. Even safety razors feature these coatings for durability. While highly durable titanium carbide blades are not indestructible. Avoid cutting on hard surfaces like glass or stone. Cleaning is straightforward usually requiring just warm soapy water. Proper care ensures these blades deliver superior cutting performance and longevity making them a worthwhile investment for serious cutting tasks.

(titanium carbide blade)

Inquiry us

if you want to want to know more, please feel free to contact us.